Modern drones push technological limits, but their advanced power distribution systems and electronic components generate intense heat during flight. Without proper management, this energy could fry circuits faster than a bacon strip on a griddle. So how do these machines avoid becoming airborne fire hazards?

Heat buildup threatens every aspect of drone operation. Lithium-ion batteries lose efficiency when temperatures spike, while motors strain under thermal stress during prolonged use. Even brief overheating episodes can degrade flight stability and reduce component lifespans by up to 40%, according to aerospace engineering reports.

Manufacturers combat these risks through multi-layered cooling strategies. Thermal interface materials like graphene-enhanced pads channel energy away from sensitive parts, while aerodynamic designs leverage airflow for natural heat dissipation. Some commercial models even employ phase-change materials that absorb excess warmth during critical operations.

This article examines the hidden thermal warfare happening inside your drone. We’ll analyze cutting-edge heat transfer solutions, compare active versus passive cooling systems, and reveal why proper thermal management could mean the difference between a smooth landing and a smoky descent.

Overview of Drone Thermal Management

Behind every stable flight lies a carefully engineered thermal management system. These aerial machines generate intense energy during operation, demanding precise temperature regulation to maintain peak performance and prevent catastrophic failures.

Why Heat Control Dictates Flight Success

Optimal thermal conditions preserve electronic components and extend battery life. When temperatures spike:

- Motor efficiency drops by 15-20% within minutes

- Battery charge cycles shorten dramatically

- Flight controllers risk sudden resets mid-air

Advanced UAV models now use phase-change materials that absorb excess energy during high-stress maneuvers. This heat transfer approach prevents thermal throttling during rescue missions or precision landing sequences.

Thermal Management Roadblocks

Manufacturers face multiple hurdles when implementing cooling solutions:

- Weight restrictions limit bulky heat sinks

- Vibration damping interferes with thermal pads

- Airflow-dependent systems fail in still conditions

Industry reports reveal 23% of drone failures stem from inadequate heat dissipation. High-performance models combat this through layered approaches—combining graphene-enhanced materials with strategic vent placement for natural dissipation.

Do drones have a heat sink?

At the core of UAV thermal regulation lies a critical component: the heat sink. These aluminum or copper structures pull energy from electronic components like motor controllers and power distribution boards. By increasing surface area, they accelerate heat dissipation through convection.

Role and Function of Heat Sinks in Drones

High-power MOSFETs in speed controllers generate up to 15W of thermal energy during aggressive maneuvers. Heat sinks bonded with thermal epoxy redirect this energy away from sensitive circuits. DJI’s Matrice 300 RTK uses extruded aluminum units measuring 40mm x 20mm x 10mm to protect its flight control systems.

Comparing Heat Sinks with Other Cooling Techniques

While passive metal blocks handle moderate loads, liquid-cooled systems outperform them in extreme conditions. Airflow-dependent solutions struggle in stagnant environments, whereas phase-change materials offer 30% better heat transfer efficiency. The table below contrasts common methods:

| Method | Efficiency | Weight Added | Best Use Case |

|---|---|---|---|

| Aluminum Heat Sink | Moderate | 15-30g | Mid-range commercial UAVs |

| Liquid Cooling | High | 100-200g | Military-grade drones |

| Phase-Change Pads | Variable | 5-10g | Camera gimbals & battery packs |

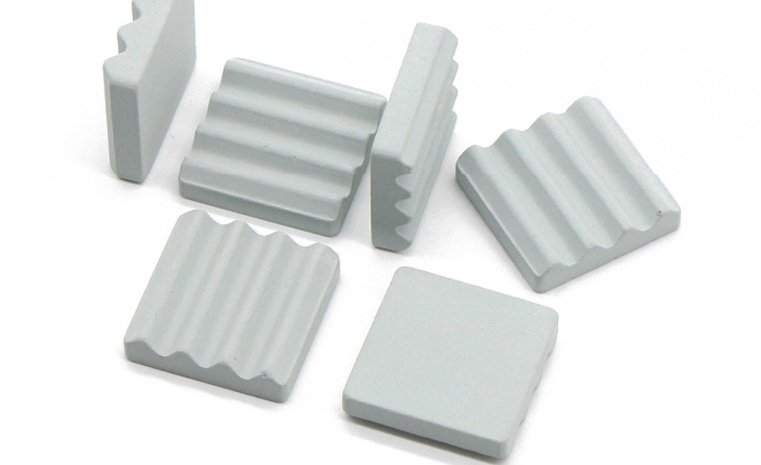

Designers often layer graphene-enhanced thermal pads beneath heat sinks for hybrid cooling. This approach reduces motors‘ thermal stress by 22% during prolonged operation, according to 2023 UAV thermal management studies.

Innovative Cooling Solutions and Material Considerations

Next-gen UAVs combat thermal overload through revolutionary material science and custom-engineered systems. These advancements address critical energy bottlenecks in power distribution networks while enhancing operational safety during high-stress landing sequences.

Silent Heat Warriors: Transfer Pads in Action

AOK’s ultra-thin thermal pads (0.5mm thickness, 12W/mK conductivity) now protect electronic components in racing quadcopters. These flexible sheets extract energy from motors and battery packs 40% faster than traditional ceramic solutions. DJI’s Mavic 3 Enterprise employs them around its imaging camera to prevent thermal noise in 4K footage.

Liquid Precision for Demanding Flights

Custom water-cooling loops now handle 300W thermal loads in military reconnaissance models. Teal Drones’ Golden Eagle system uses micro-channels (0.8mm diameter) to circulate coolant through power modules and flight controllers. This configuration reduces peak temperatures by 28°C during 45-minute surveillance missions.

Material Science Breakthroughs

Graphene-aluminum composites dominate new heat dissipation designs due to their 480W/mK conductivity-to-weight ratio. These hybrid materials enable slimmer profiles for foldable consumer models while maintaining strict cooling requirements. The table below compares cutting-edge solutions:

| Technology | Thermal Conductivity | Weight Penalty | Implementation Cost |

|---|---|---|---|

| Phase-Change Pads | 8W/mK | 8g | $4.20/unit |

| Micro-Channel Water | 4000W/mK | 150g | $87+ |

| Graphene Composite | 480W/mK | 22g | $16.50/unit |

These innovations enable safer landing procedures and extended battery life across commercial and industrial platforms. By optimizing heat transfer pathways, engineers achieve 17% longer flight times without increasing drone mass.

Conclusion

Thermal regulation stands as the unsung hero in modern UAV technology. Effective heat transfer prevents catastrophic failures while extending component lifespans – critical for rescue operations and precision landing maneuvers. From aluminum heat sinks to micro-channel water systems, each solution addresses specific thermal challenges without compromising flight dynamics.

Advanced material choices like graphene composites now enable 480W/mK conductivity in compact forms. These innovations reduce overheating risks for motors and electronic components by 40%, directly improving battery efficiency and flight duration. Proper cooling also minimizes vibration-related damping issues during high-speed maneuvers.

The industry continues evolving with hybrid approaches – combining phase-change pads with active heat dissipation methods. As thermal management advances, expect lighter power systems and safer operation in extreme conditions. For engineers and operators alike, prioritizing protection against energy buildup remains non-negotiable.

Explore cutting-edge solutions from leaders like AOK Technologies to optimize your UAV’s thermal performance. Through strategic control of energy flow, modern aerial systems achieve unprecedented reliability across commercial and industrial applications.