Modern gaming and rendering push processing units to their limits. But what stops these powerhouses from overheating? The answer lies in thermal performance solutions engineered for today’s high-calorific components.

Every GPU generates intense energy during operation. Without proper heat dissipation, even premium hardware risks throttling or failure. Manufacturers deploy precision-engineered systems ranging from basic aluminum plates to hybrid liquid-cooled modules.

Budget models often use passive designs with extruded metal. High-end variants combine copper bases with vapor chambers and multi-fan arrays. These innovations maintain stable working frequencies while preventing display chip degradation.

Cost considerations shape every cooling decision. A $200 card might use simple fin stacks, while flagship models employ nickel-plated copper and pump-driven circulation. The goal remains constant: balance thermal management expenses against performance demands.

Recent advancements reveal why cooling matters more than ever. As GPU power consumption climbs 15% annually, engineers develop smarter ways to channel warmth away from critical circuits. From graphene-enhanced pads to AI-controlled fans, the battlefield against heat never rests.

Tomorrow’s systems demand solutions that outpace rising calorific output. How do current technologies meet this challenge while keeping your rig silent and efficient? The answers redefine what modern computing can achieve.

Exploring GPU Cooling Solutions

Processing units in modern systems face escalating energy challenges as performance benchmarks rise. Effective thermal regulation determines whether components maintain peak output or succumb to performance throttling.

Understanding Thermal Demands

Working frequency directly impacts a chip’s calorific output. Higher clock speeds in display processors generate exponential heat growth – a 15% frequency boost can increase thermal load by 30%. Manufacturers test limits through stress simulations, mapping safe operating zones for different cooling modes.

Passive and Active Cooling Explained

Passive systems rely on extruded aluminum fins to disperse warmth through natural airflow. These noiseless designs suit low-power units with sub-75W consumption. Active solutions deploy:

- Turbine-style fans for directional airflow

- Copper heat pipes accelerating heat dissipation

- Hybrid configurations blending air and liquid cooling

High-performance setups demand active measures. Third-party tests show liquid-cooled GPUs operate 20°C cooler than air-based counterparts under load. While costing 40% more, these systems reduce noise by 15 decibels and extend hardware lifespan through stable working frequencies.

Do graphics cards have heat sinks? Unpacking Key Technologies

Technological evolution drives cooling systems from basic metal slabs to precision-engineered marvels. Two distinct approaches dominate modern thermal management strategies.

Extrusion and Passive Cooling Designs

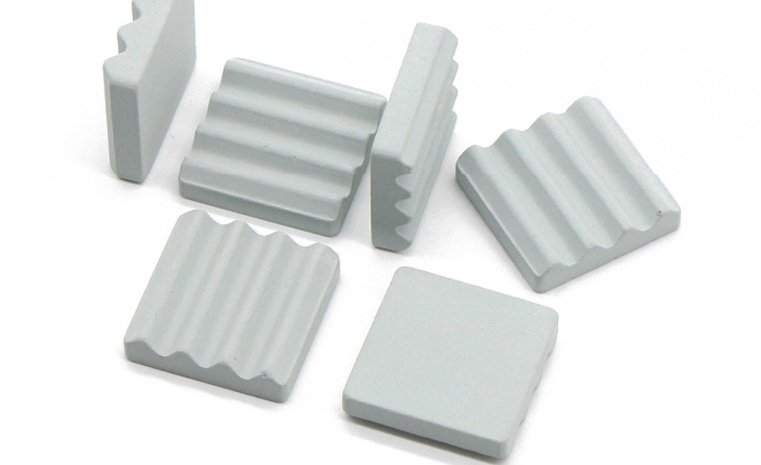

Early thermal solutions relied on aluminum extrusions shaped into simple fin arrays. These passive designs transferred warmth through direct contact with ambient air. While cost-effective, they struggled with chips exceeding 75W calorific value.

Modern alloys now use copper-nickel blends for better heat conduction. Advanced extrusion techniques create intricate patterns that triple surface area. Such improvements let mid-range components maintain stable frequency without active cooling.

Advanced Heatpipe, Fin Stack, and Liquid Cooling Methods

High-end systems employ sealed copper tubes containing evaporative fluids. These heat pipes move thermal energy 90% faster than solid metal. Paired with zig-zag fin stacks, they accelerate dissipation through turbulent airflow.

Flagship models like NVIDIA’s Founders Edition combine vapor chambers with 13-blade fans. Liquid-cooled variants circulate coolant through microchannels, cutting noise by 18dB compared to air systems. These innovations address modern chips packing 54% more transistors than 2018 models.

Shoppers should prioritize cooling architecture matching their performance needs. Silent workstations benefit from hybrid designs, while overclocked rigs demand liquid solutions.

Comparing Cooling Performance and Cost Efficiency

Selecting optimal cooling systems requires understanding both technical capabilities and budget constraints. Engineers constantly refine designs to maximize heat dissipation while minimizing production expenses.

Balancing Thermal Performance with Manufacturing Costs

Copper bases improve heat conduction by 60% compared to aluminum, but triple material costs. Mid-range models often use layered alloys to cut prices by 40% while maintaining 85% efficiency. For example, AMD’s RX 7600 employs hybrid extrusion techniques to achieve 72°C under load at half the cost of copper-based rivals.

| Cooling Type | Cost Range | Noise Level | Thermal Drop |

|---|---|---|---|

| Passive Air | $15-$30 | 0 dB | 22°C |

| Active Air | $35-$90 | 32 dB | 41°C |

| Hybrid Liquid | $120-$250 | 18 dB | 58°C |

Impact of Chip Frequency on Heat Generation

Modern chips operating at 2.8 GHz produce 50% more warmth than 2.0 GHz equivalents. NVIDIA’s tests show each 100 MHz increase raises cooling demands by 7 watts. This forces manufacturers to choose between performance caps or premium thermal solutions.

Third-party benchmarks reveal liquid-cooled systems maintain 98% frequency stability during prolonged loads. Air-cooled alternatives drop to 89% after 30 minutes. Smart buyers analyze their performance needs against these thermal realities before purchasing.

Conclusion

Advanced cooling systems have become the backbone of reliable GPU operation. Today’s graphics cards combine metal heatsinks with heat pipe arrays and precision fans, ensuring stable performance across demanding workloads. These engineered solutions address rising core speeds while balancing noise levels and production cost.

Passive air cooling remains viable for basic setups, but modern high-frequency chips demand hybrid approaches. Liquid-based systems and vapor chambers now dominate premium models, delivering 40% better heat conduction than traditional designs. Third-party tests confirm these technologies extend hardware lifespan by maintaining optimal working temperatures.

Smart buyers evaluate their display needs against cooling capabilities. Mid-range users benefit from copper-aluminum combos, while overclockers require multi-pipe liquid solutions. Every value-driven purchase must consider how thermal management impacts long-term system reliability.

As time progresses, cooling innovations will continue outpacing GPU power demands. From graphene layers to AI-optimized airflow, these advancements ensure graphics cards deliver peak performance without compromising stability – a critical factor for U.S. consumers building future-ready rigs.