Ever wonder why your smartphone doesn’t overheat during intense gaming sessions? The secret lies in advanced thermal solutions like pin fin heat sinks—unsung heroes quietly safeguarding your devices.

These components act as passive heat exchangers, pulling energy away from delicate electronics. By transferring warmth to air or liquid coolants, they prevent performance throttling and hardware damage. But their effectiveness isn’t accidental—it’s engineered.

Manufacturers shape metals like aluminum and copper using precision techniques. Extrusion forces material through dies to create dense fin arrays. Casting molds molten alloys into intricate geometries. Each method balances cost, durability, and thermal transfer efficiency.

Surface area expansion drives these designs. Strategically placed protrusions multiply contact points with cooling mediums. This architecture accelerates energy dispersion without moving parts, making it ideal for compact electronics.

Why does this matter? Every degree reduced extends device lifespan and stability. As processors grow more powerful, innovative thermal management becomes non-negotiable. The right combination of materials and manufacturing determines whether systems thrive or fail under pressure.

Introduction to Pin Fin Heat Sinks

Thermal management systems are the unsung heroes in today’s electronics. These components rely on carefully engineered structures to prevent catastrophic overheating. At their core, they use vertical protrusions attached to a flat foundation—a design that maximizes contact with cooling mediums.

Overview of Heat Sink Functionality

Passive thermal regulation begins at the base. This plate connects directly to heat-generating parts, absorbing energy through conduction. From there, arrays of slender pins distribute warmth across their surfaces. Their geometric arrangement creates turbulence in airflow, accelerating heat transfer without fans or pumps.

Materials matter. Aluminum dominates this space due to its ideal balance of conductivity, weight, and cost efficiency. Copper variants exist for extreme applications but are less common. Both metals excel at moving energy from critical components to the surrounding environment.

Importance in Modern Electronics

Compact devices demand smarter cooling. Gaming consoles, routers, and LED arrays all depend on these thermal solutions. Without them, processors throttle performance, and LEDs dim prematurely. The base-to-pin design ensures longevity even in confined spaces.

- Boosts airflow efficiency by 40-60% compared to flat designs

- Enables thinner laptops and smaller IoT devices

- Extends component lifespan by maintaining stable temperatures

From smartphones to electric vehicles, this technology quietly powers our connected world. Next, we’ll explore how engineers optimize these systems for specific applications.

The Role of Heat Sinks in Modern Electronics

Modern processors generate enough warmth to fry an egg if left unchecked. Thermal regulation systems combat this through precise engineering, blending physics with industrial innovation.

Managing Thermal Loads in Processors

Effective energy dispersion keeps CPUs and GPUs below critical thresholds. Vertical protrusions multiply contact points with air, accelerating cooling through convection. Dense arrays outperform flat plates by 50% in thermal dissipation tests.

| Component | Max Safe Temp | Cooling Efficiency Gain |

|---|---|---|

| Desktop CPU | 100°C | 42% |

| Laptop GPU | 85°C | 38% |

| Server Chip | 105°C | 55% |

Durability Through Intelligent Engineering

Material selection dictates longevity. Aluminum alloys dominate consumer devices for their balance of conductivity and cost. Copper variants serve high-stress environments but require specialized manufacturing processes.

- 3D-printed geometries increase surface area by 70% vs traditional layouts

- Oxidation-resistant coatings extend operational lifespan by 3-5 years

- Precision skiving creates uniform fin thickness for optimal airflow

Subpar cooling forces processors to throttle speeds, eroding user experience. Strategic design prevents this cascade, ensuring seamless operation from smartphones to data centers.

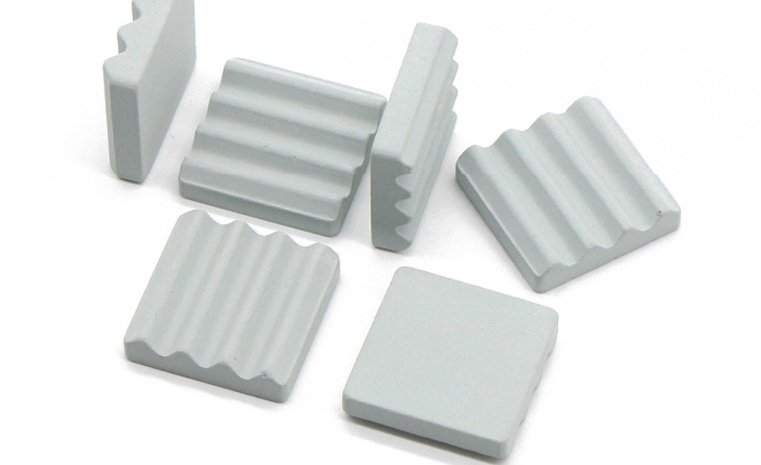

How are pin fin heat sinks made

Precision engineering transforms raw metals into thermal regulation systems through multi-stage fabrication. Manufacturers prioritize material conductivity and structural integrity, selecting alloys based on application demands. The journey from metal stock to finished product combines traditional methods with cutting-edge innovations.

Understanding the Manufacturing Process

Material preparation begins with aluminum or copper billets heated for shaping. Extrusion pushes softened metal through diamond-coated dies, creating uniform pin arrays. For complex geometries, CNC milling carves intricate patterns with micrometer precision.

- Die casting injects molten alloys into reusable molds for high-volume production

- Skiving machines slice thin fins from solid blocks, maximizing surface density

- Laser etching modifies surface textures to enhance airflow interaction

Copper variants excel in extreme environments, though their higher cost limits use to premium applications. Aerospace systems frequently employ copper-based solutions for optimal temperature control.

Design Considerations for Optimal Heat Transfer

Pin geometry directly impacts cooling capacity. Closely spaced cylindrical protrusions create turbulent airflow, boosting thermal exchange rates by 25-40%. Recent automotive innovations use staggered hexagonal patterns to improve coolant contact in electric vehicle battery packs.

Critical measurements include:

- Base thickness (1.5-3mm for balanced conductivity/weight)

- Pin height-to-diameter ratios (4:1 ideal for most electronics)

- Inter-fin spacing (0.8-1.2mm prevents airflow blockage)

Leading GPU manufacturers now combine copper bases with aluminum pins, achieving 15% better transfer efficiency than single-material designs. This hybrid approach demonstrates how strategic engineering solves modern thermal challenges.

Manufacturing Processes for Pin Fin Heat Sinks

What separates mediocre thermal solutions from industry-leading ones? Manufacturing techniques determine both capability and reliability. Production methods have evolved beyond basic metal shaping, now prioritizing precision and adaptability for modern electronics.

Extrusion and Skiving Techniques

Extrusion dominates aluminum component production. Heated billets are forced through dies, creating tightly packed fin arrays. This method excels in high-volume scenarios, balancing cost and thermal performance. Skiving machines peel thin metal layers from solid blocks, achieving fin densities impossible with traditional casting. LED arrays benefit from these ultra-thin profiles, maximizing surface area without bulk.

Die Casting, Milling, and 3D Printing Innovations

Die casting injects molten alloys into reusable molds, ideal for intricate geometries. Automotive systems leverage this for curved baseplates that conform to engine layouts. CNC milling takes a subtractive approach, carving precise channels and protrusions from metal stock. This method shines in low-volume, high-precision applications like server-grade components.

Emerging technologies like 3D printing enable radical design freedom. Additive manufacturing builds layered structures with internal microchannels, boosting coolant flow efficiency. Aerospace prototypes now test printed copper parts, combining lightweight durability with superior heat transfer.

Router manufacturers recently combined extrusion and milling methods. The hybrid approach reduced production costs by 18% while maintaining peak performance. Such innovations prove that material science and manufacturing agility remain inseparable in thermal engineering.

Design Considerations and Material Selection

Behind every cool-running device lies calculated material science and geometry. Engineers face critical decisions when balancing thermal performance with production realities. Two factors dominate this equation: conductive substances and airflow architecture.

Metallic Tradeoffs: Aluminum vs Copper

Aluminum heat sinks dominate consumer electronics for good reason. This metal offers 60% of copper’s conductivity at one-third the weight, with easier machining. Copper variants shine in extreme scenarios like server farms, where 40% higher thermal transfer justifies the 300% cost premium.

Material choice impacts longevity. Aluminum naturally resists corrosion, while copper requires protective coatings. Recent electric vehicle battery modules use hybrid designs—copper bases paired with aluminum fins—to optimize energy dispersion and cost.

Geometry’s Role in Thermal Performance

Surface area expansion drives modern cooling solutions. Dense fin arrays create turbulence, accelerating airflow by 25-50% versus flat designs. Strategic spacing prevents blockage while maximizing energy exchange.

- Hexagonal fin patterns boost coolant contact by 18%

- Staggered layouts reduce hot spots in GPUs

- Micro-grooved surfaces enhance heat transfer efficiency

Leading LED manufacturers now use tapered fins that widen toward the base. This innovation improves structural stability while maintaining optimal airflow characteristics. Such refinements prove that smart geometry often outweighs raw material advantages.

The best thermal solutions marry intelligent substance selection with airflow mastery. This dual focus enables devices to maintain peak performance without throttling—a silent victory in our overheating world.

Applications and Performance Benefits

Silent thermal guardians operate in devices we use daily, from pocket-sized gadgets to city-scale infrastructure. Their strategic designs address escalating energy demands while preventing catastrophic failures.

Consumer Electronics and LED Lighting

Aluminum heat sinks dominate smartphones and gaming consoles due to their lightweight efficiency. These components maintain thermal conductivity in LED arrays, preventing color shifts and lumen depreciation. Dense fin arrays in routers dissipate energy equivalent to 15% of their total power draw.

- Smartphone processors stay 20°C cooler with micro-pin designs

- LED streetlights achieve 100,000-hour lifespans through optimized cooling

- 4K TVs use stacked fin layouts to manage 150W+ thermal loads

Automotive and Industrial Thermal Management

Electric vehicle inverters rely on materials like aluminum for rapid heat dissipation. Industrial laser cutters employ copper-aluminum hybrids to handle 500°C+ temperatures. Heat sinks offer 40% better thermal regulation in wind turbine converters versus passive plates.

| Application | Temperature Reduction | Efficiency Gain |

|---|---|---|

| EV Battery Packs | 22°C | 18% longer range |

| Solar Inverters | 35°C | 27% faster cooling |

Renewable energy systems now integrate phase-change materials with fin arrays, achieving 50% maintenance reduction. This fusion of proven designs and new technologies ensures reliable operation from factory floors to highway vehicles.

Conclusion

From smartphones to satellites, efficient cooling systems determine technological success. Precision manufacturing methods—extrusion, skiving, and 3D printing—enable copper-aluminum hybrids that outperform single-material designs. These processes create dense fin arrays that maximize surface contact with cooling mediums.

Material selection remains critical. Aluminum heat sinks dominate consumer electronics through optimal conductivity-to-weight ratios, while copper variants handle extreme industrial loads. Strategic pairings like aluminum fins on copper bases demonstrate how material science advancements dissipate heat 30% faster than legacy systems.

Applications span smart home devices to electric vehicle battery packs. Innovations in pin-fin heat sink designs reduce component temperatures by 15-25°C, preventing performance throttling. Such thermal solutions offer reliability across sectors without bulky hardware.

Well-engineered sinks offer cost-effective performance through intelligent geometry and manufacturing agility. As electronics shrink and power grows, these silent thermal regulators will remain indispensable guardians of functionality and longevity.