IGSINK specializes in custom stamped heat sink solutions with advanced stamping technology. As a leading Chinese manufacturer, we deliver high-performance aluminum and copper stamped heat sinks for diverse industrial applications.

Our stamped heat sinks combine superior thermal performance with cost-effective manufacturing, making them ideal for medium to high-volume production requirements.

Lower tooling costs and simplified manufacturing process make stamped heat sinks an economical choice for your thermal management needs.

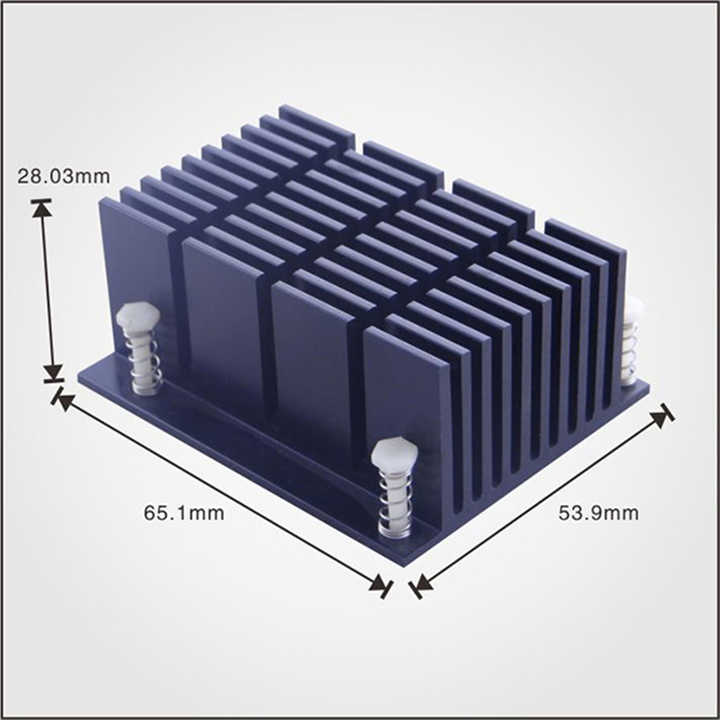

Stamped heat sinks offer excellent thermal performance while maintaining extremely light weight, perfect for space-constrained applications.

Our stamping process is optimized for medium to high-volume manufacturing, ensuring consistent quality and fast delivery times.

Advanced stamping technology enables extremely thin fins, providing larger surface area for superior heat dissipation performance.

We offer fully customized stamped heat sink designs tailored to your specific thermal requirements and application constraints.

Stamped heat sinks are designed for quick and easy assembly, reducing production time and assembly costs for your products.

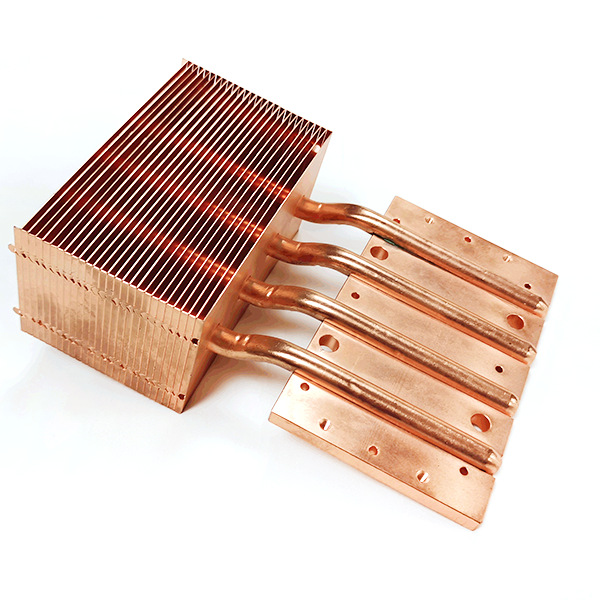

Our advanced stamping technology transforms metal sheets into high-performance thermal management solutions through precision progressive punching processes.

High-quality aluminum or copper sheets are prepared and cut to precise dimensions for the stamping process.

Metal sheets undergo progressive punching through specialized dies, creating detailed fin structures with each stamp.

Zipper fins are formed during the stamping process, creating interlocking structures for enhanced strength and thermal performance.

Stamped fins are assembled to heat sink bases using soldering or mechanical fastening, followed by surface finishing treatments.

We use premium aluminum and copper materials to manufacture stamped heat sinks that meet the highest industry standards for thermal performance and reliability.

Our stamped heat sinks are engineered to deliver optimal thermal performance across a wide range of operating conditions and power requirements.

IGSINK stamped heat sinks are widely used across various industries for efficient thermal management solutions in low to medium power applications.

IGSINK offers comprehensive manufacturing capabilities from design to production, ensuring high-quality stamped heat sinks that meet your exact specifications.

Our experienced engineers provide complete design support, thermal analysis, and prototyping services for custom stamped heat sink solutions.

Advanced stamping equipment and automated production lines capable of handling volumes from 1,000 to 1,000,000+ pieces annually.

Comprehensive quality control system including dimensional inspection, thermal testing, and material verification to ensure consistent quality.

Multiple surface finish options including anodizing, powder coating, electroplating, and custom finishes for enhanced performance and appearance.

Efficient supply chain management and global shipping capabilities to ensure timely delivery of your stamped heat sink orders.

Dedicated technical support team providing application guidance, installation assistance, and ongoing customer service.

IGSINK maintains the highest quality standards through rigorous testing procedures and internationally recognized certifications.

Quality Management System

Environmental Standards

Performance Verification

Composition Verification

Ready to discuss your custom stamped heat sink requirements? Contact our technical team today for personalized solutions and competitive pricing.

Address

Dadan (No. 1), Heshan Village, Yuanzhou Town, Boluo County, Huizhou City, Guangdong Province, China

Response Time

Within 24 hours