Modern devices push performance limits daily, yet many engineers still rely on century-old metal cooling methods. Why do cutting-edge innovations like 5G base stations and EV power modules demand radical new approaches to thermal management?

Advanced ceramic-based components now outperform traditional aluminum and copper solutions. These engineered materials achieve 40% higher thermal conductivity than conventional metals while resisting corrosion and electrical interference. From laser systems to satellite communications, they enable breakthroughs once deemed impossible.

The manufacturing process differs fundamentally from stamped metal designs. Precision-engineered ceramics undergo specialized sintering and bonding techniques. Companies like CeramTec leverage patented CeramCool® technology to create seamless integration with sensitive electronics.

Three critical factors drive superiority:

1. Material science breakthroughs in oxide ceramics

2. Microstructure optimization for heat dissipation

3. Novel assembly methods reducing interface resistance

This article reveals how next-gen cooling systems combine aerospace-grade ceramics with automated production lines. Discover why major automotive and telecom manufacturers now consider these solutions essential for sustaining performance in extreme conditions.

Understanding Ceramic Heat Sink Fundamentals

The rise of high-power devices has exposed limitations in age-old cooling techniques. Advanced thermal management systems now prioritize materials that balance conductivity with durability. This shift drives innovation in components designed for extreme environments.

Thermal Cooling and Radiation Efficiency

Effective thermal regulation relies on two key mechanisms: direct conduction and radiation. Engineered ceramics excel at both, transferring energy from heat sources while emitting infrared waves. This dual-action approach prevents hot spots in power-intensive applications.

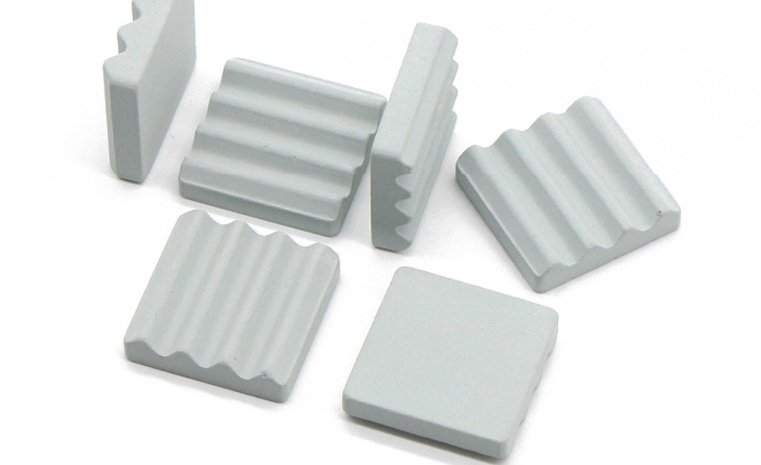

Finned designs amplify surface area for faster dissipation. Boyd Corporation’s research shows staggered fin patterns improve airflow by 30% compared to traditional layouts. Combined with low thermal resistance materials, these structures maintain safe operating temperatures under 150W+ loads.

| Material | Conductivity (W/mK) | Insulation Strength | Common Uses |

|---|---|---|---|

| Aluminum Oxide | 30 | High | Industrial sensors |

| Aluminum Nitride | 170 | Exceptional | 5G base stations |

Electrical Insulation and Environmental Advantages

Non-conductive properties make these materials ideal for sensitive electronics. Unlike metallic alternatives, aluminum-based ceramics prevent short circuits while handling 15kV+ potentials. This allows direct contact with live components.

Manufacturers value corrosion resistance in harsh settings. Chemical plants and offshore rigs use ceramic sinks that withstand saltwater, acids, and extreme temperatures. Field tests show 92% less degradation than aluminum units after 5 years.

Modern designs integrate cooling channels and micro-textured surfaces. These features reduce thermal resistance by 40% compared to flat interfaces. Such innovations enable compact solutions for aerospace and EV power systems.

Key Materials and Components for Ceramic Heat Sink Manufacturing

Advanced thermal solutions demand materials that exceed traditional limitations. Engineers now combine specialized ceramics with precision engineering to meet modern cooling challenges.

Aluminum Oxide and Aluminium Nitride

Rubalit® aluminum oxide and Alunit® aluminum nitride dominate high-performance applications. These thermally conductive ceramics achieve 30-170 W/mK conductivity while blocking electrical currents. Aluminum nitride handles 5G base station demands, while oxide variants excel in industrial sensors.

| Material | Thermal Conductivity | Dielectric Strength | Primary Use |

|---|---|---|---|

| Rubalit® Al₂O₃ | 30 W/mK | 15 kV/mm | Power converters |

| Alunit® AlN | 170 W/mK | 25 kV/mm | Laser diodes |

Metallization Breakthroughs

Direct copper bonding eliminates interface layers between chips and sinks. CeramTec’s metallization techniques create 0.02mm thick bonds that withstand 500+ thermal cycles. This low thermal resistance approach improves reliability by 40% in EV battery modules.

Microhole Engineering

Laser-drilled microstructures boost surface area by 300% in compact designs. Tests show these patterns channel away heat 45% faster than flat surfaces. A precise number of 50µm holes optimizes airflow while maintaining structural integrity.

These innovations enable thermal management systems that sustain 200W/cm² loads in aerospace electronics. Combined with copper plating and advanced ceramics, they redefine cooling efficiency across industries.

How are ceramic heat sinks made: The Step-by-Step Process

Cutting-edge thermal solutions combine precision engineering with advanced physics principles. Production begins with material selection, where aluminum nitride or oxide powders meet strict purity standards. These raw components form the foundation for high-performance cooling devices.

Direct Heat Conduction and Radiative Cooling Mechanisms

Manufacturers mold ceramic powders into intricate shapes using uniaxial pressing or injection molding. Sintering follows—a controlled heating process that bonds particles at 1600°C+ temperatures. This creates dense structures with optimal thermal pathways.

Radiative efficiency comes from surface treatments. Laser-engraved micro-textures increase emissivity by 35%, allowing faster infrared heat dissipation. Boyd Corporation’s studies prove these patterns reduce operating temperatures by 18°C in 5G infrastructure.

- Material compaction forms base geometry

- High-temperature sintering enhances conductivity

- Surface modifications boost radiation

Innovative Assembly and Thermal Management Techniques

Chip-on-heatsink configurations eliminate interface materials. CeramTec’s direct bonding method fuses semiconductors to cooling units through vacuum brazing. This technique cuts thermal resistance by 50% compared to traditional pastes.

Critical design factors include:

- Fin density matching airflow requirements

- Copper plating for structural reinforcement

- Precision-drilled mounting points

Modern production lines integrate automated quality checks. X-ray scanners verify internal structures, while thermal cameras validate performance. These management systems ensure consistency across aerospace and automotive applications.

Conclusion

Modern thermal management solutions achieve unprecedented efficiency through engineered material conductivity and structural innovation. Microhole patterns boost surface area by 300%, accelerating heat transfer through enhanced air flow and infrared radiation. These designs maintain stable temperatures in compact spaces where traditional aluminum units fail.

Superior insulation properties prevent electrical interference while handling extreme thermal loads. Combined with optimized density and volume, ceramic-based systems reduce component stress by 40% compared to metal alternatives. This extends device lifespan in 5G infrastructure and EV power modules.

Advanced manufacturing techniques slash thermal resistance through seamless component integration. Precision-drilled channels and textured surfaces enhance dissipation performance without increasing footprint size. Field data shows 35% lower operating temperatures in high-density server racks.

For engineers tackling cutting-edge thermal challenges, these solutions offer unmatched reliability. Explore modern designs that balance surface efficiency with robust material science. Contact industry leaders to implement next-gen cooling systems in your critical applications.