IGSINK delivers superior heat sink sandblasting services combining advanced surface treatment technology with precision manufacturing. Our sandblasting process enhances thermal performance, improves coating adhesion, and provides uniform surface finish for optimal heat dissipation.

High-pressure abrasive blasting removes oxidation, contaminants, and surface imperfections while creating optimal micro-texture for enhanced thermal conductivity and coating adhesion.

Every sandblasted heat sink undergoes rigorous inspection for surface consistency, texture uniformity, and dimensional accuracy following industry best practices and ISO standards.

Our sandblasting operations utilize enclosed systems with advanced dust collection, silica-free abrasives, and proper ventilation to ensure worker safety and environmental compliance.

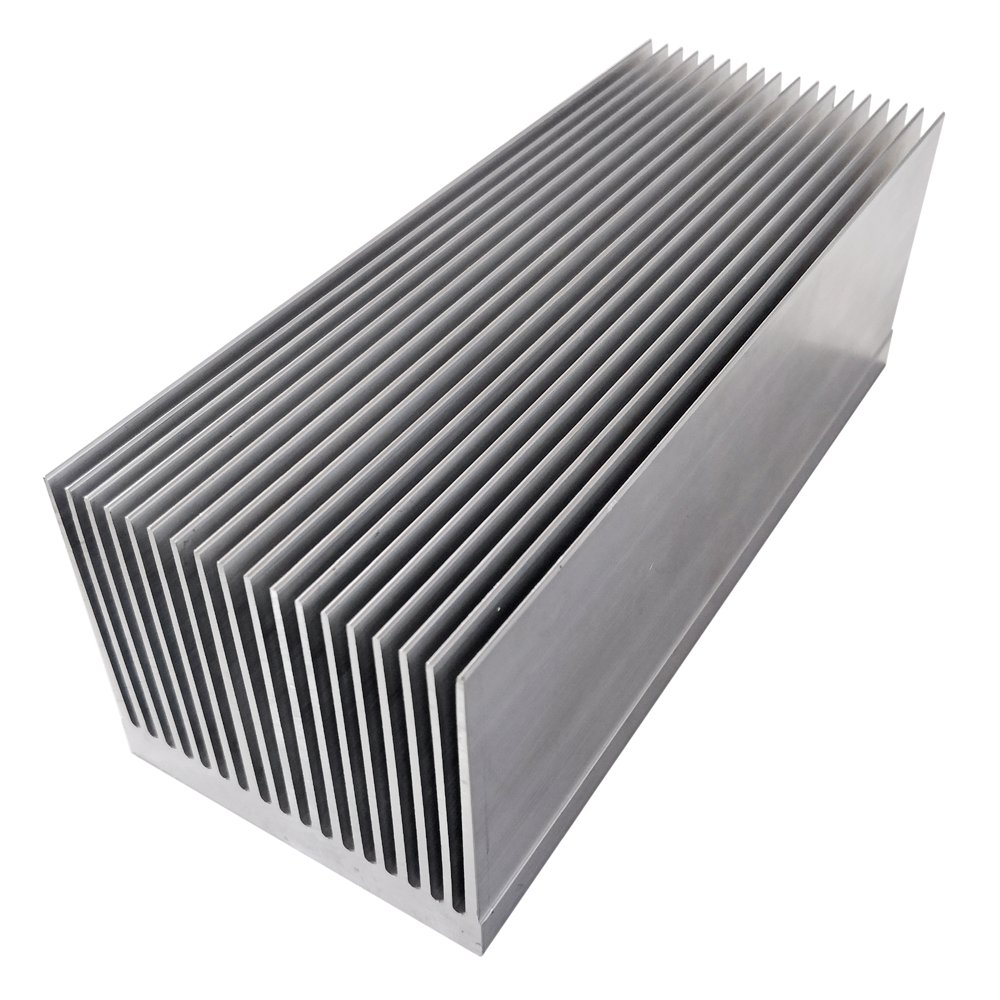

IGSINK employs state-of-the-art sandblasting equipment and precision-controlled processes to deliver consistent, high-quality surface treatments for aluminum heat sinks across various applications.

6063-T5 aluminum profiles heated to 520-540°C for optimal extrusion quality and thermal performance characteristics.

Precision machining including drilling, milling, and grooving combined with sandblasting for complex heat sink geometries.

High-pressure die casting for dense, complex fin designs with integrated sandblasting surface treatment.

Increased surface area and improved thermal conductivity through optimized surface roughness and texture.

Enhanced coating adhesion for anodizing, powder coating, and other surface finishes with extended durability.

Complete removal of oxidation, contaminants, machining marks, and surface imperfections for uniform appearance.

Enhanced fatigue resistance and mechanical properties through controlled surface stress and texture modification.

CPU coolers, GPU heat sinks, power amplifiers, LED lighting systems

Engine cooling, transmission coolers, electric vehicle thermal management

Power electronics, motor drives, welding equipment, industrial automation

Avionics cooling, satellite thermal systems, aircraft electronics

As a leading Chinese manufacturer, IGSINK combines advanced sandblasting technology with precision manufacturing to deliver superior heat sink solutions for global markets.

Proven expertise in heat sink manufacturing and surface treatment technologies

Efficient logistics and quality control for international customers

Tailored sandblasting processes for unique heat sink requirements

Dadan (No. 1), Heshan Village, Yuanzhou Town, Boluo County, Huizhou City, Guangdong Province, China