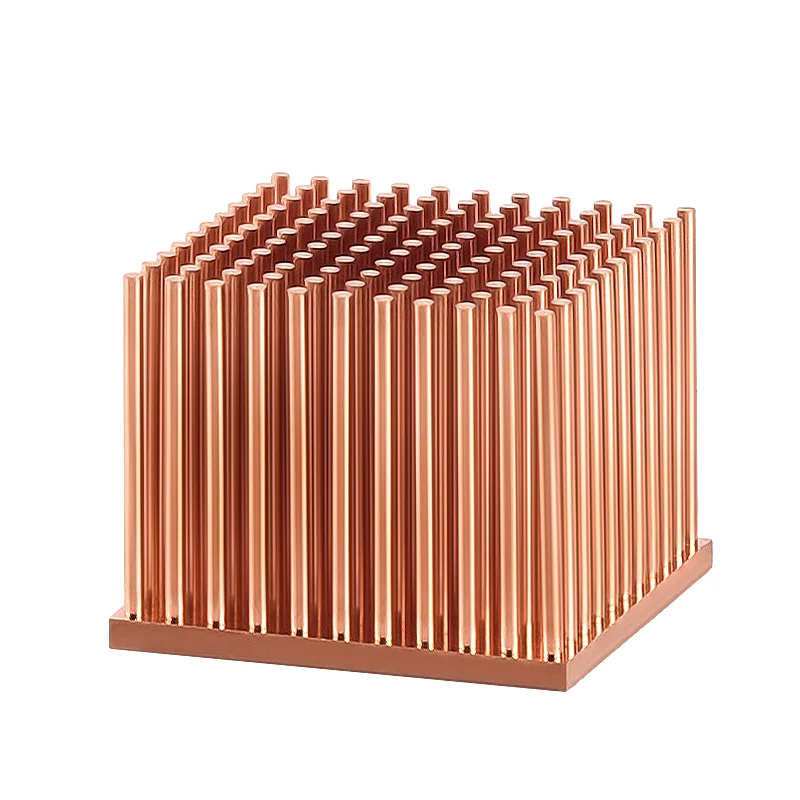

Professional Custom Cold Forging Heat Sink Solutions

As a leading Cold Forged Heat Sink Manufacturers in China, IGSINK specializes in producing high-performance custom cold forged heat sinks using advanced cold forging technology. Our cold forging process delivers superior thermal conductivity, exceptional surface finish, and outstanding dimensional accuracy.

13% better thermal conductivity compared to extruded heat sinks

High aspect ratio up to 50:1 with excellent dimensional tolerance

Capable of producing intricate pin fin and elliptical designs

No secondary machining required, reducing production costs

Our advanced cold forging process transforms raw aluminum and copper materials into high-performance heat sinks at room temperature using precisely controlled pressure.

High-quality aluminum alloy AL1050, AL6063, or copper C1100 billets are precisely prepared for cold forging process.

Material is shaped at room temperature under extreme pressure, creating superior grain structure and thermal properties.

Surface treatment including anodizing, powder coating, and rigorous quality inspection ensure optimal performance.

IGSINK provides comprehensive custom Cold Forged Heat Sink solutions tailored to your specific thermal management requirements. Our engineering team works closely with clients to optimize heat sink design for maximum efficiency.

Omnidirectional airflow capability with maximum surface area for superior cooling performance

Reduced pressure drop and enhanced heat transfer efficiency for high-performance applications

Compact design with high fin density for space-constrained applications

Specialized shapes and configurations designed for specific thermal requirements

High-power LED chips, COB modules, and spotlight applications requiring efficient heat dissipation

CPUs, GPUs, power modules, and high-performance electronic components

Electric vehicle controllers, power inverters, and automotive electronic systems

Wind power converters, PV inverters, and energy storage systems

Base stations, power amplifiers, and communication equipment cooling

High-power medical equipment and precision instruments requiring reliable thermal management

Understanding the advantages of cold forged heat sinks compared to alternative manufacturing methods

ISO certified manufacturing with rigorous quality control processes

State-of-the-art cold forging equipment and precision tooling

Dedicated engineering team for custom design and technical support

Ready to discuss your custom Cold Forged Heat Sink requirements? Get in touch with our experienced team today.

Dadan (No. 1), Heshan Village,

Yuanzhou Town, Boluo County,

Huizhou City, Guangdong Province, China

IGSINK – Leading Cold Forged Heat Sink Manufacturers & Suppliers in China

Specializing in custom cold forged heat sink solutions for superior thermal management