IGSINK specializes in custom aluminum extruded heat sink solutions with advanced manufacturing capabilities. As leading extruded heat sink suppliers, we deliver precision-engineered thermal management solutions for global industries.

As experienced extruded heat sink manufacturers, we combine advanced aluminum extrusion technology with precision engineering to deliver superior thermal management solutions.

State-of-the-art aluminum extrusion equipment and precision machining capabilities for complex heat sink profiles.

Tailored extruded heat sink designs with comprehensive engineering support from concept to production.

ISO certified manufacturing processes ensuring consistent quality and performance standards.

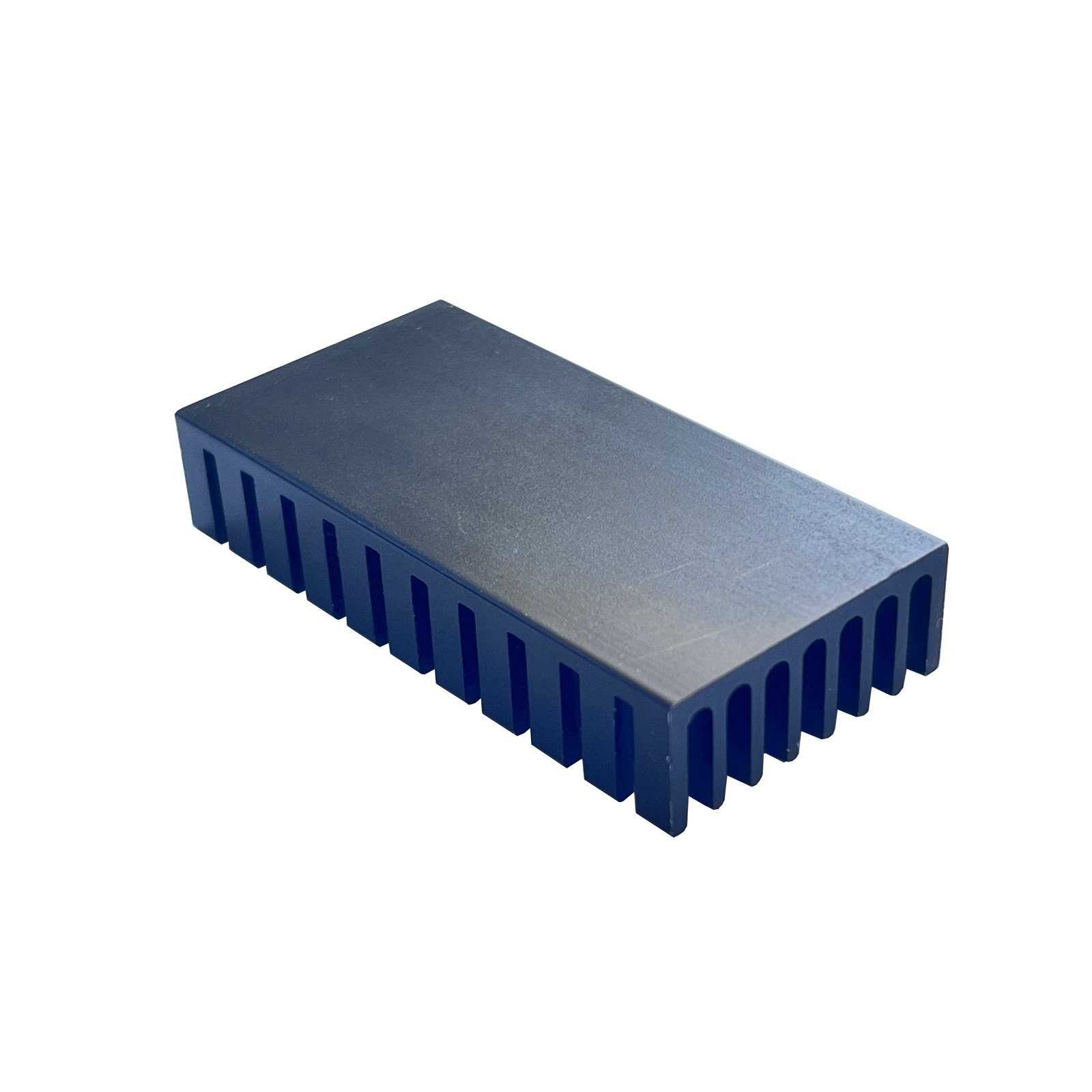

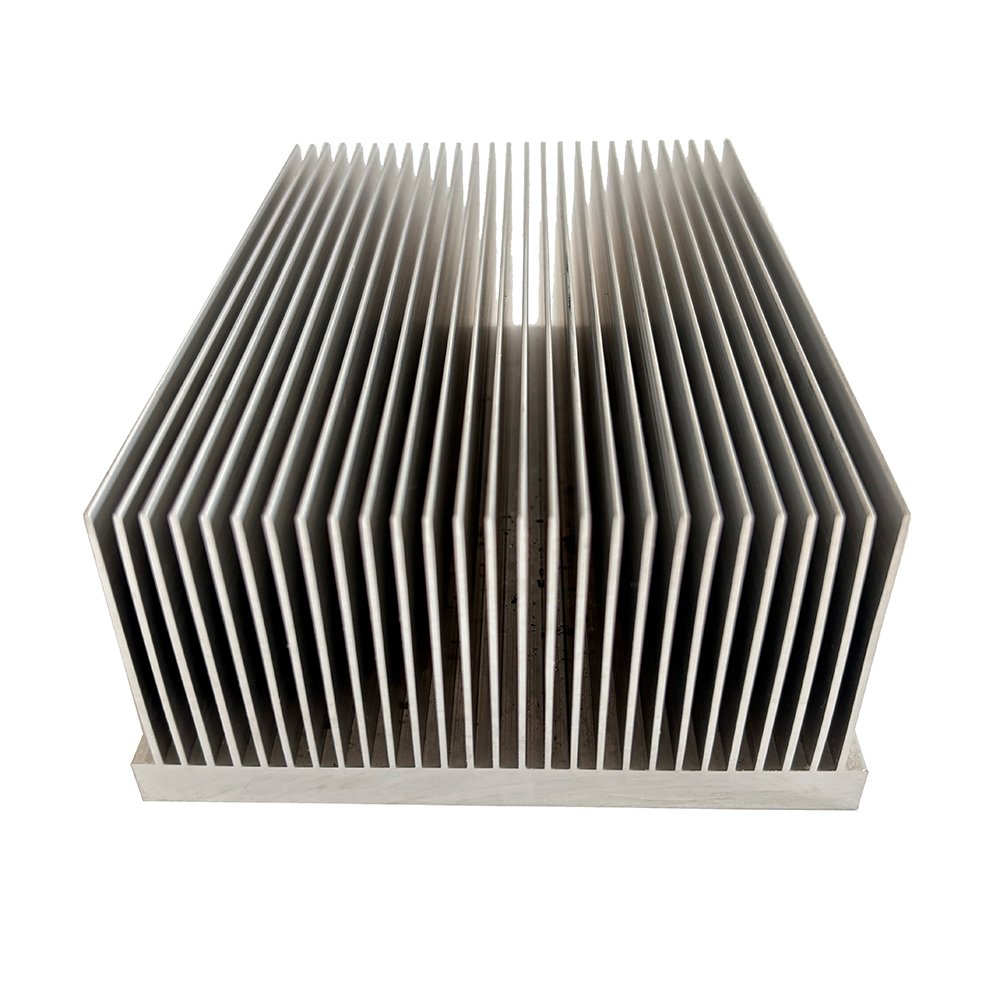

Our high-performance aluminum extruded heat sinks are designed for demanding applications requiring superior thermal dissipation. Available in various sizes and configurations to meet specific cooling requirements.

As leading extruded heat sink suppliers, we offer extensive customization capabilities for unique thermal management challenges. Our engineering team works closely with clients to develop optimal cooling solutions.

High-grade aluminum billets are heated to optimal temperature for extrusion process, ensuring consistent material properties.

Advanced extrusion presses force heated aluminum through custom dies to create precise heat sink profiles with tight tolerances.

CNC machining, drilling, tapping, and surface treatments to meet specific application requirements and enhance performance.

Custom extruded heat sinks for CPUs, GPUs, power supplies, and electronic control units requiring efficient thermal management.

Specialized heat sink profiles for LED luminaires, street lighting, and high-power LED applications ensuring optimal thermal performance.

Heat sinks for electric vehicle inverters, charging systems, and automotive electronic modules with stringent reliability requirements.

5G base stations, power amplifiers, and telecommunications equipment requiring robust thermal solutions for continuous operation.

Power electronics, motor drives, and industrial automation systems benefiting from custom extruded heat sink solutions.

Solar inverters, wind turbine controllers, and energy storage systems requiring efficient thermal management solutions.

IGSINK maintains rigorous quality standards throughout the manufacturing process, ensuring every extruded heat sink meets or exceeds customer specifications and industry requirements.

Partner with IGSINK for professional extruded heat sink solutions. Our experienced engineering team is ready to help you design and manufacture the perfect thermal management solution for your application.

Get in touch with our team for custom extruded heat sink solutions and technical support.

Address

Dadan (No. 1), Heshan Village, Yuanzhou Town, Boluo County, Huizhou City, Guangdong Province, China

Professional extruded heat sink manufacturers with advanced capabilities

Custom engineering support from concept to production

Competitive pricing with flexible minimum order quantities

Quality assurance and international certifications