IGSINK is a leading Chinese manufacturer specializing in advanced heat sink technologies for thermal management solutions. Our comprehensive range of manufacturing processes delivers superior cooling performance for electronics, automotive, LED lighting, and industrial applications.

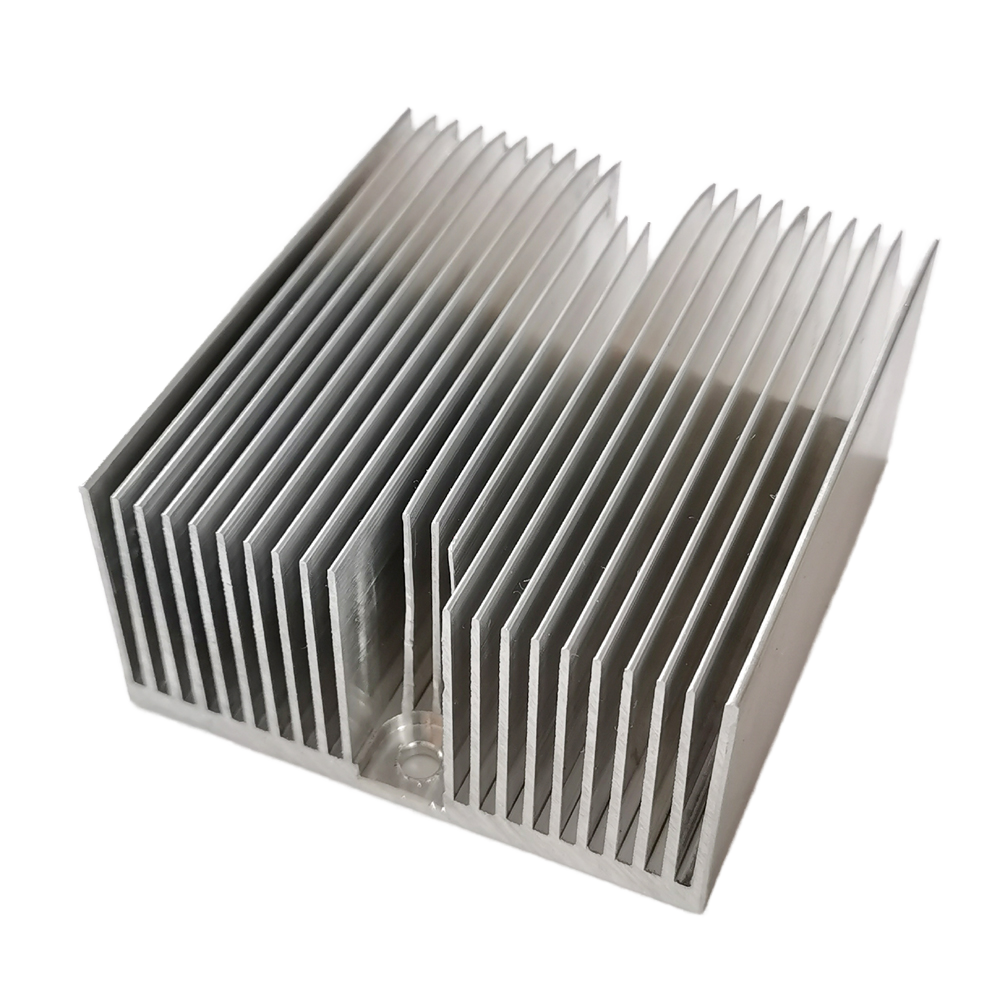

Cost-effective aluminum extrusion process for standard cooling applications with excellent thermal conductivity.

Precision skiving technology for thin, high-density fins with superior heat dissipation performance.

Progressive stamping process for lightweight, cost-effective cooling solutions with design flexibility.

Advanced bonding technology combining different materials for optimized thermal performance.

Cold forging process for high-strength, precision heat sinks with excellent microstructure integrity.

Interlocking fin design for high-density cooling with excellent heat dissipation efficiency.

Explore our comprehensive range of heat sink technologies and thermal management solutions

Advanced manufacturing processes for superior heat sink performance

Our extrusion process utilizes advanced die technology to create uniform fin profiles with excellent thermal conductivity. This cost-effective method is ideal for high-volume production of standard heat sink profiles.

Material Options:

Capabilities:

Precision skiving process creates ultra-thin fins with high aspect ratios, delivering superior heat dissipation performance for high-power applications.

Advantages:

Applications:

Progressive stamping process offers design flexibility and cost-effectiveness for medium to high-volume production with lightweight construction.

Features:

Materials:

Advanced bonding processes combine different materials to optimize thermal performance while maintaining structural integrity.

Bonding Methods:

Benefits:

Cold forging process produces high-strength heat sinks with excellent microstructure integrity and precision geometries.

Characteristics:

Applications:

Interlocking fin design creates high-density cooling solutions with optimal airflow characteristics and efficient heat dissipation.

Design Features:

Performance:

Premium materials for optimal thermal performance

Aluminum offers excellent thermal conductivity, lightweight construction, and cost-effectiveness, making it ideal for most heat sink applications.

Alloy Options:

Properties:

Copper provides superior thermal conductivity for high-performance applications requiring maximum heat dissipation efficiency.

Grades Available:

Properties:

Professional heat sink solutions for various applications

6061 aluminum flexible heat sink with 160mm profile for LED high bay lighting applications.

6000 series custom heat sink with large surface area for enhanced cooling performance.

Competitive price cylindrical heat sink with reliable thermal performance for specialized applications.

Heat sink technologies serving diverse industrial applications

CPU cooling, GPU thermal management, power electronics, and server applications requiring efficient heat dissipation.

High-power LED cooling systems for street lighting, commercial fixtures, and specialized lighting applications.

Electric vehicle battery cooling, power inverters, charging systems, and automotive electronics thermal management.

5G base stations, networking equipment, RF amplifiers, and communication device thermal solutions.

Motor drives, inverters, welding equipment, and industrial automation systems requiring robust thermal management.

Solar inverters, wind power converters, energy storage systems, and renewable energy infrastructure cooling.

Technical specifications and performance metrics

State-of-the-art production facilities and quality control

From concept to production – complete thermal management solutions

CAD modeling, thermal simulation, and optimization

Rapid prototyping and testing validation

Full-scale manufacturing and quality control

Global shipping and logistics support

Your trusted partner for advanced thermal management solutions

Decades of expertise in thermal management and heat sink manufacturing

Serving customers worldwide with reliable shipping and support

Tailored heat sink designs for your specific applications

Quick turnaround times from design to production

ISO certified manufacturing with comprehensive quality control

Expert engineering support throughout the project lifecycle

Get in touch for custom heat sink solutions and technical support

Speak with our engineering team

Available 24/7 for technical inquiries

Get quotes within 24 hours

Fast prototyping and production

Dadan (No. 1), Heshan Village, Yuanzhou Town, Boluo County, Huizhou City, Guangdong Province, China

State-of-the-art production facility with advanced equipment and quality control systems

Worldwide delivery with reliable logistics partners

Contact our engineering team today for custom heat sink solutions