IGSINK – Advanced Soldered Heat Sink Solutions for High-Performance Thermal Management

IGSINK specializes in manufacturing custom soldering heat sinks using advanced welding technology. Our soldered heat sink solutions provide superior thermal conductivity and reliability for high-performance electronic cooling applications.

As professional soldering heat sink suppliers, we utilize environmentally friendly lead-free medium temperature soldering processes to weld fins on aluminum or copper bases, ensuring optimal heat dissipation performance.

Manufacturing Experience

Custom Projects

Quality Certified

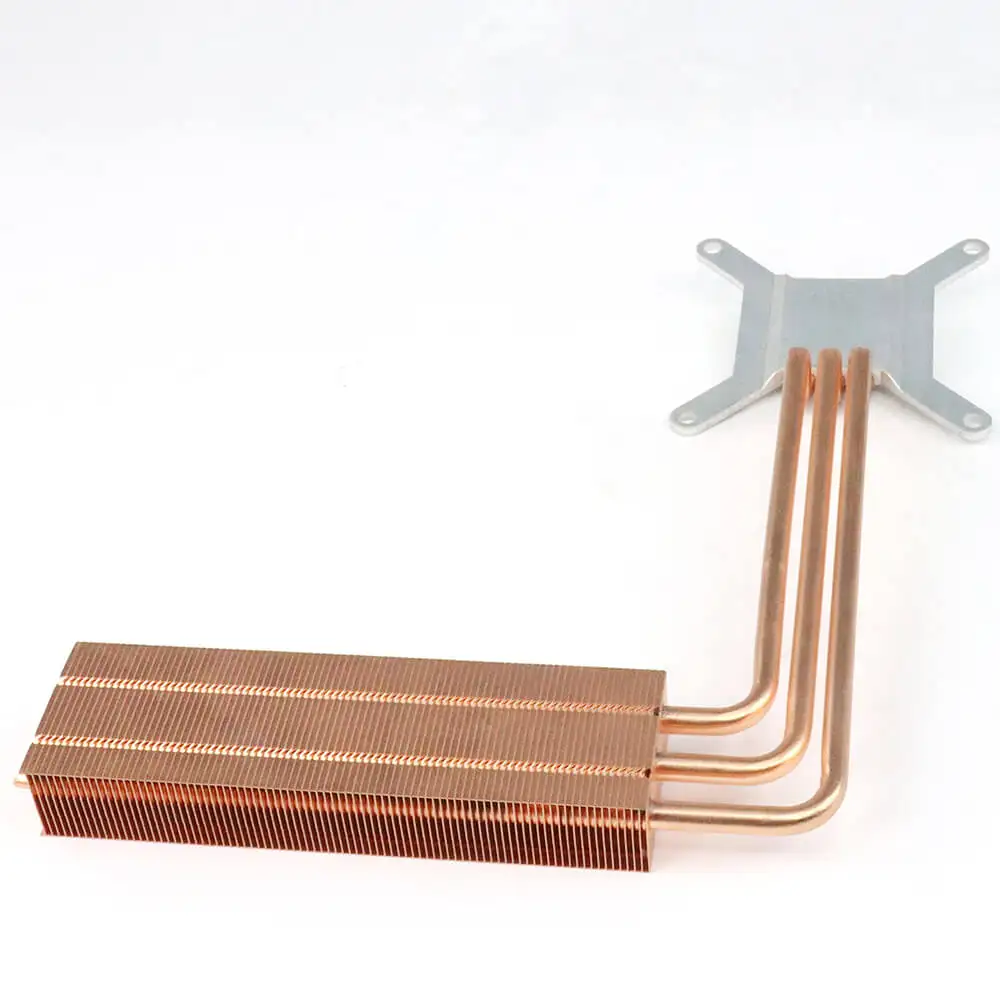

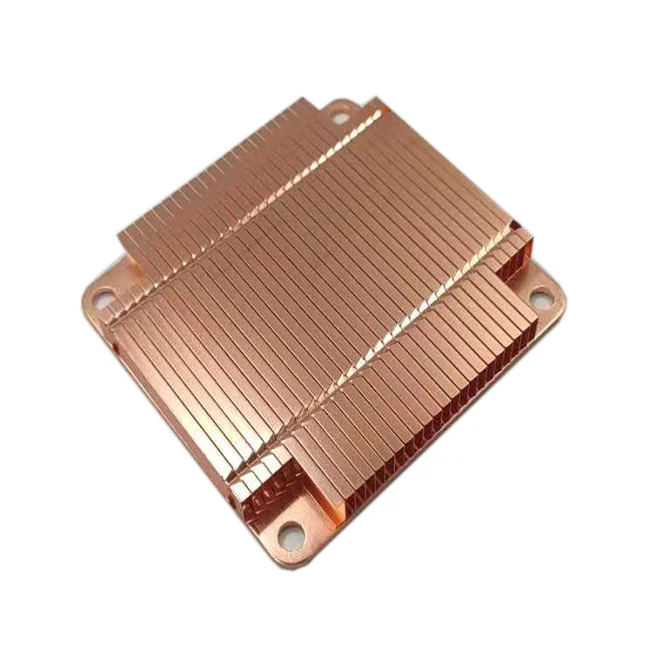

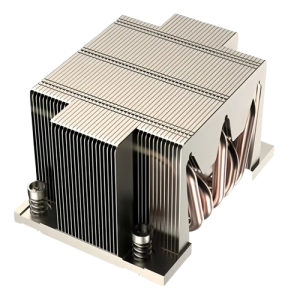

Our custom soldering heat sinks feature precision-welded fins and heat pipes for maximum thermal performance in demanding electronic applications.

Our soldering heat sink manufacturing utilizes advanced welding technology to bond fins on aluminum or copper bases. We employ both high-temperature (700-800°C) and low-temperature (200-300°C) soldering processes depending on application requirements.

We work with premium materials to ensure optimal thermal performance:

High-density heat dissipation capability with fins as thin as 0.1-0.4mm for concentrated heat sources

Custom tooling and stamping capabilities for complex geometries and high-volume production

Lead-free soldering process with environmental protection standards compliance

CPU, GPU, power modules, and high-performance semiconductors

Laptop cooling modules, server heat sinks, and desktop thermal solutions

High-power LED arrays and lighting fixtures requiring efficient heat management

Power electronics, inverters, and high-frequency devices

Advanced zipper fin soldering heat sinks for CPU, LED, and electronic component cooling with superior thermal performance.

Surface cleaning and nickel plating preparation for optimal bonding

Precision application of lead-free solder paste on base plates

Precise positioning of fins and heat pipes using specialized fixtures

High-temperature reflow process at 180-230°C for strong bonding

Comprehensive testing and inspection for thermal performance

Surface treatment and final cleaning for optimal performance

Advanced soldering technology enables seamless integration of heat pipes for enhanced thermal performance in demanding applications.

Our engineering team provides comprehensive design support from concept to production, ensuring optimal thermal performance for your specific application requirements.

IGSINK’s flexible manufacturing approach allows us to serve both prototype development and large-scale production requirements efficiently.

Quality management system certification

Lead-free environmental protection standards

Comprehensive thermal performance validation

Contact IGSINK today for custom soldering heat sink solutions tailored to your specific thermal management requirements.

Dadan (No. 1), Heshan Village, Yuanzhou Town,

Boluo County, Huizhou City, Guangdong Province, China