IGSINK delivers premium custom zipper heat sink solutions with advanced stamping technology and superior thermal management performance

IGSINK specializes in manufacturing high-performance zipper heat sinks using advanced stamping technology. Our custom zipper heat sink solutions provide superior thermal management for electronics, LED lighting, telecommunications, and industrial applications.

State-of-the-art stamping technology and precision manufacturing processes ensure consistent quality and performance in every zipper heat sink.

Tailored zipper heat sink designs to meet specific thermal requirements, with flexible materials, dimensions, and surface finishing options.

ISO certified manufacturing processes and comprehensive quality control ensure reliable performance and durability of our zipper heat sinks.

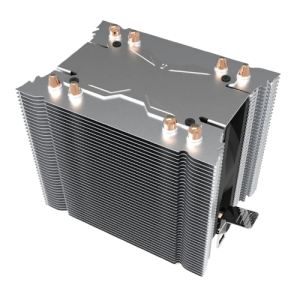

Zipper heat sinks represent an innovative thermal management solution that combines high fin density with lightweight construction. These specialized heat sinks are manufactured using advanced stamping technology that creates interlocking fins from thin metal sheets.

The unique zipper fin design allows for exceptional heat dissipation performance while maintaining structural integrity. The stamping process creates precise interlocking grooves that enable the fins to connect seamlessly, forming a robust thermal interface.

High-quality aluminum or copper sheets are cut to precise dimensions for stamping operations.

Advanced stamping technology creates interlocking zipper fins with precise tolerances and optimal geometry.

Zipper fins are assembled and bonded to the base plate using soldering, brazing, or epoxy techniques.

Surface treatments such as anodizing, plating, or coating are applied for enhanced performance and durability.

Our state-of-the-art stamping equipment ensures precise dimensional control and consistent quality across all zipper heat sink production runs. The process allows for complex geometries and high aspect ratio fins that maximize heat dissipation efficiency.

We optimize material usage through efficient stamping patterns and minimize waste while maintaining structural integrity. Our process enables the production of fins with thickness ranging from 0.1mm to 2mm depending on material and application requirements.

IGSINK utilizes premium aluminum and copper materials for zipper heat sink manufacturing, each offering unique advantages for specific applications. Our material selection ensures optimal thermal performance, durability, and cost-effectiveness.

Aluminum 6063 and 1050 alloys provide excellent thermal conductivity (166-201 W/mK) with lightweight construction and cost-effective manufacturing.

Copper C1100 offers exceptional thermal conductivity (400 W/mK) for high-power applications requiring maximum heat dissipation performance.

IGSINK zipper heat sinks are engineered for diverse applications across multiple industries. Our custom solutions provide reliable thermal management for electronic devices, LED lighting systems, telecommunications equipment, and power electronics.

Superior heat dissipation capabilities with high fin density and optimized surface area for maximum thermal transfer efficiency.

Optimized weight-to-performance ratio through efficient material usage and advanced stamping technology.

Efficient manufacturing process and material utilization provide excellent value for high-volume production applications.

Customizable dimensions, materials, and configurations to meet specific thermal management requirements.

Robust construction and proven manufacturing processes ensure consistent performance and long service life.

Pre-tooled designs and efficient manufacturing processes enable quick turnaround times for custom orders.

| Feature | Zipper Heat Sink | Extruded Heat Sink | Skived Heat Sink |

|---|---|---|---|

| Fin Density | High | Medium | High |

| Weight | Light | Medium | Medium |

| Cost | Low | Low | High |

| Customization | High | Medium | Medium |

| Production Volume | High | High | Low |

IGSINK provides complete custom zipper heat sink design services from initial concept to final production. Our experienced engineering team works closely with customers to develop optimized thermal solutions that meet specific performance requirements and constraints.

Expert thermal analysis and design optimization to ensure maximum heat dissipation efficiency for your specific application requirements.

Fast prototype development and testing to validate design concepts and performance before full-scale production.

Complete manufacturing services including tooling design, production planning, and quality assurance for custom zipper heat sinks.

With over a decade of experience in thermal management solutions, IGSINK is the trusted partner for custom zipper heat sink manufacturing in China. Our commitment to quality, innovation, and customer satisfaction makes us the preferred choice for global customers.

Proven expertise in thermal management and heat sink manufacturing

Serving customers worldwide with reliable shipping and support

State-of-the-art manufacturing equipment and processes

Dedicated engineering team and responsive customer service

ISO 9001:2015 certified manufacturing processes and comprehensive quality control systems ensure consistent product quality.

Direct manufacturer pricing with no intermediary costs, providing excellent value for custom zipper heat sink solutions.

Efficient production planning and logistics ensure quick turnaround times for both prototype and production orders.

Ready to optimize your thermal management with custom zipper heat sinks? Contact IGSINK today for expert consultation and competitive pricing.

Dadan (No. 1), Heshan Village, Yuanzhou Town, Boluo County, Huizhou City, Guangdong Province, China

Power dissipation, thermal resistance, dimensions, and operating conditions

Drawings, material preferences, surface finish, and mounting requirements

Quantity requirements, timeline, and specific application information